Electrical steel plate, also known as silicon steel sheet, refers to a very low carbon content (after annealing, carbon content in 0.005% below) of ferrosilicon soft magnetic alloy silicon content is generally 0.5%-4.5%. Adding silicon to iron can increase its resistivity and permeability. With the characteristics of low iron loss and high magnetic induction, high-performance electrical steel is the preferred material for making efficient, large-capacity motors and energy-saving transformers. The carbon emission reduction equivalent value of electrical steel per ton orientation is 17 tons. The energy efficiency of electrical equipment and household appliances largely depends on the electromagnetic properties of electrical steel.

Electrical plates are divided into two categories, namely oriented electrical plates and unoriented electrical plates. The oriented electrical steel plate refers to the electrical steel plate with a certain orientation grain. The rolling magnetic properties of this kind of electrical steel plate are obviously better than the transverse ones. It is mainly used for transformers and is produced by cold rolling process. The unoriented electrical steel plate refers to the electrical steel plate with random grain orientation. This kind of electrical steel plate rolling direction and transverse magnetic roughly the same, mainly used in motors.

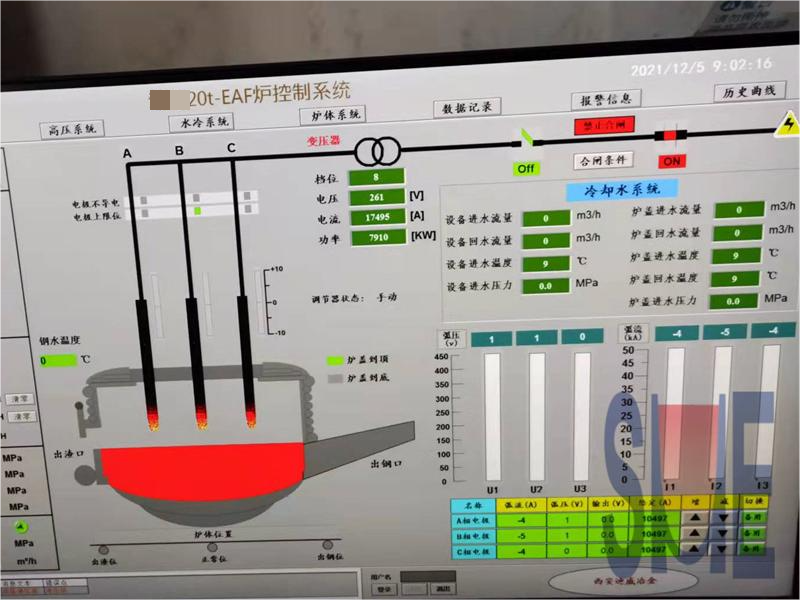

The production process of high magnetic orientation electrical steel: Steelmaking (continuous casting, refining, etc.) → hot rolling (low temperature slab heating technology) → normal pickling → cold rolling (hot rolling at one time) → continuous decarbonizing annealing nitriding → coating magnesium oxide → high temperature annealing (advanced circular furnace process to achieve secondary recrystallization) → stretching → surface coating insulation → laser scoring (magnetic domain refining technology) → shear packaging, etc.

The production process of high-quality non-oriented electrical steel: steelmaking (continuous casting, refining, etc.) → hot rolling → normal pickling → cold continuous rolling or single stand cold rolling → continuous annealing (double cold rolling, continuous annealing) → coating, etc.