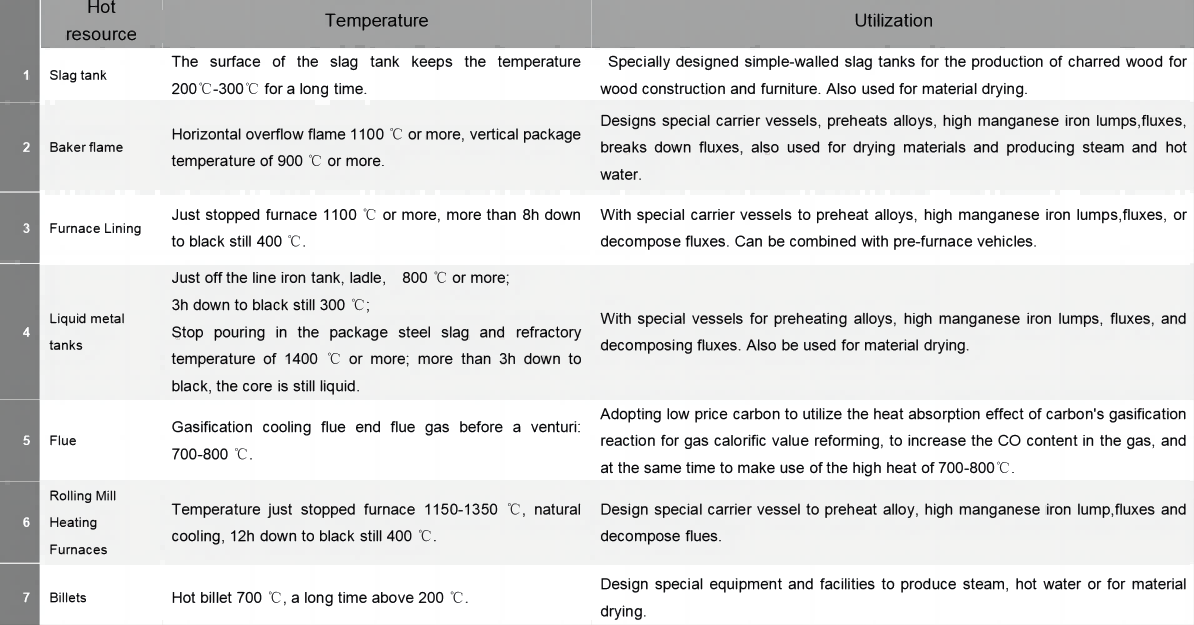

| Hot Resource | Temperature | Manner of utilization | |

|---|---|---|---|

| 1 | Slag Canister | The surface of the slag tank keeps the temperature 200℃-300℃ for a long time. | Specially designed simple-walled slag tanks for the production of charred wood for wood construction and furniture. Also used for material drying. |

| 2 | Baking bag flame | Horizontal overflow flame 1100 ℃ or more, vertical package temperature of 900 ℃ or more. | Designs special carrier vessels, preheats alloys, high manganese iron lumps,fluxes, breaks down fluxes, also used for drying materials and producing steam and hot water. |

| 3 | Furnace Lining | Just stopped furnace 1100 ℃ or more, more than 8h down to black still 400 ℃. | With special carrier vessels to preheat alloys, high manganese iron lumps,fluxes, or decomposing fluxes. Can be combined with pre-furnace vehicles. |

| 4 | Liquid metal tanks | Just off the line iron tank, ladle, ladle temperature of 800 ℃ or more, more than 3h down to black still 300 ℃; stop pouring in the package steel slag and refractory temperature of 1400 ℃ or more, more than 3h down to black, the core is still liquid. | With special vessels for preheating alloys, high manganese iron lumps, fluxes, decomposing fluxes. Also be used for material drying. |

| 5 | Flue | Gasification cooling flue end flue gas before a venturi: 700-800 ℃. | Adopting low price carbon to utilize the heat absorption effect of carbon's gasification reaction for gas calorific value reforming, to increase the CO content in the gas, and at the same time to make use of the high heat of 700-800℃. |

| 6 | Rolling Mill Heating Furnaces | Temperature just stopped furnace 1150-1350 ℃, natural cooling, 12h down to black still 400 ℃. | Design special carrier vessel to preheat alloy, high manganese iron lump, melt and decompose the melt. |

| 7 | Billets | Discharing billet 700 ℃, a long time above 200 ℃. | Design special equipment and facilities to produce steam, hot water or for material drying. |

The table in picture form: